- Opening Time :10:00 AM to 6:00 PM

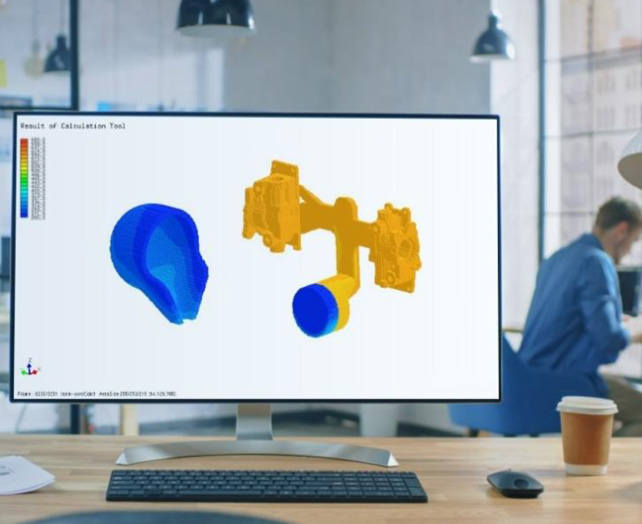

We provide casting simulation based engineering solutions for casting industry. Using physics based approach we simulate accurately the metal flow in the die cavity, heat transfer and solidification, predict the defects such as shrinkage porosity, air entrapment, blow holes, hot tear, cold shut, mis-run, etc. We can predict warpage/ distortions by analysing the residual stress formation in the casting. With help of these insights we assist casting engineers to conduct multiple number of iterative trials on the computer, helping them to optimize the process, and gating design quickly.

We have helped several hundreds of casting companies/ foundries to reduce the rejections, and increase the yield and productivity. In this site, we keep adding case studies of success stories of casting simulation on a regular basis.

Most trusted & recommended by millions of company

Most trusted and recommended by foundries